ELIM spol. s r.o. electronic & LED light

1993

The story of ELIM spol. s r.o.

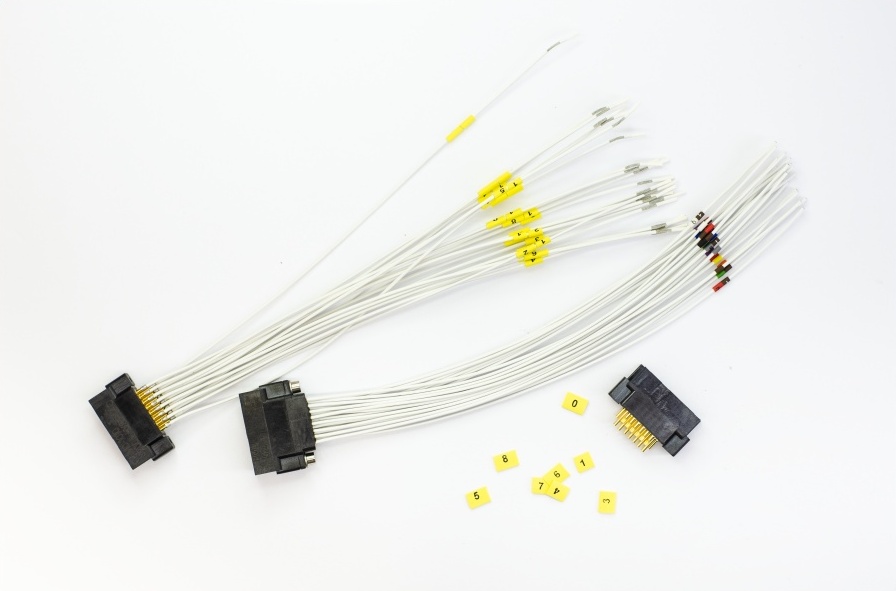

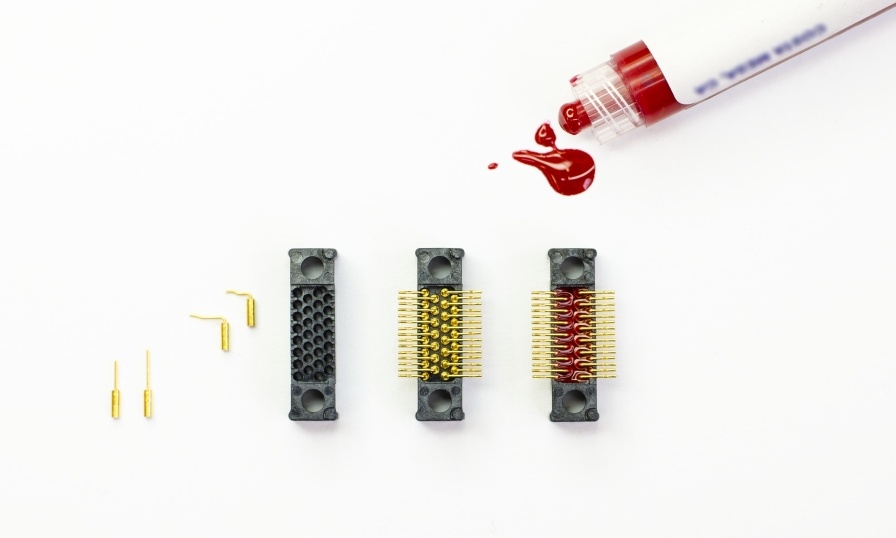

we started to write in 1993. From the set up, the company has been working at the field of electrical engineering and electronics. We have successfully realized a number of orders from development, prototype to mass production. Since then, our firm has grown for a company that can offer top-level services in that kind of industry.

2004

The first LED bulb made in Czech Republic

Key year for the ELIM. We were the first in Czech Republic who used LED technology in the world of light. The results of our effort was the first LED bulb.

2020

Within almost of 30 years of ELIM

were our customers well-known companies like ŠKODA Auto, REALPROGRES Letiště Praha, Model Obaly Opava… We have done for them the electronic development.

In addition to the Czech Republic, we currently supply our products and services to Germany, Italy, France, UK, Norway…The motto of 90 employees is: not to sell, but to fulfill the wishes and needs of the all customers who ask us for a solution.

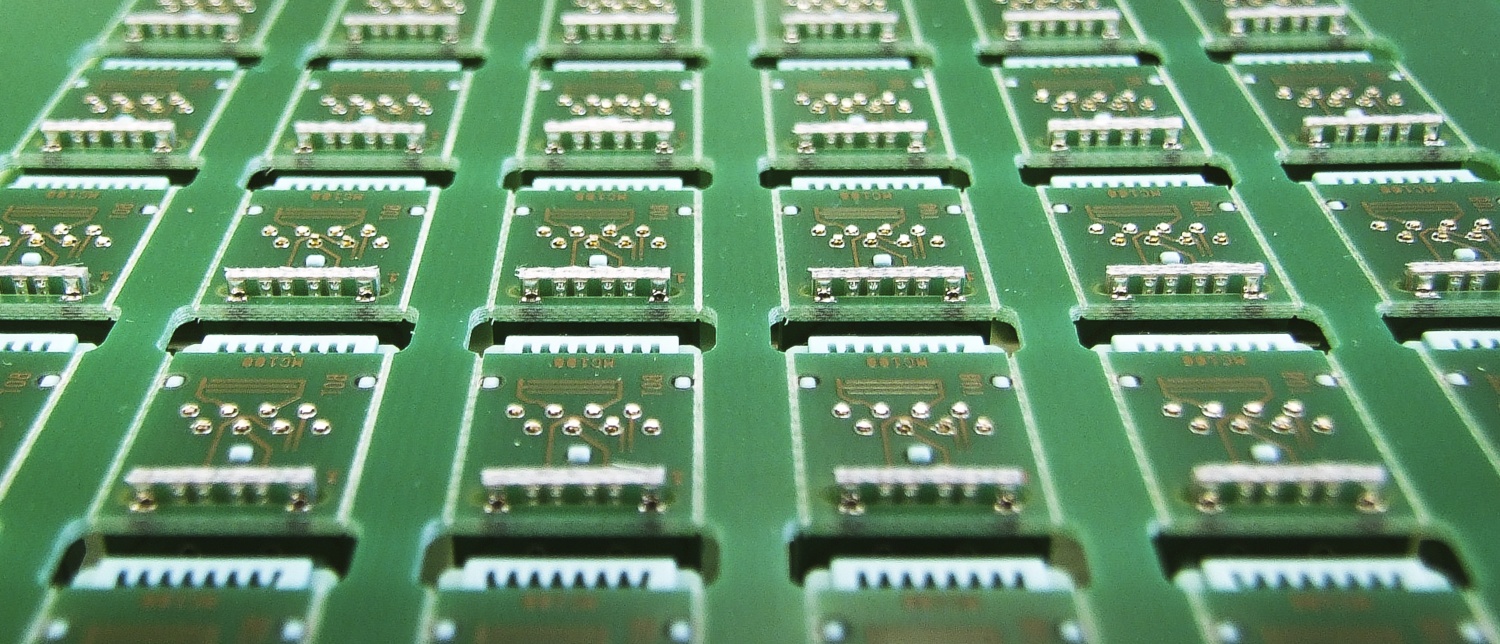

References of our important customers at the field of EMS ( Electronics manufacturing services):

Air and sea transport

Military industry

Space program

Automation and robotics

Food

Medical